|

|

日本語はこちら

Takayuki Watanabe

Professor

Department of Chemical Engineering

Kyushu University

Field of study : Plasma Chemistry, Energy Engineering

Key words : Plasma Processing, Modeling of Plasma Flow, Nanomaterials,

Waste Treatment, Lunar Resource Utilization

http://www.chem-eng.kyushu-u.ac.jp/lab5/index-e.html/

September 29, 2025

|

|

|

ISPC25 (Kyhoto, Japan) May 21-26, 2023 |

NEWS

- May, 2025: Review Paoper "Thermal Plasma System for Innovative Materials Processing" was published on Reviews of Modern Plasma Physics.

- March, 2024: Plasma Chemistry and Plasma Processing, Special Issue, Papers by Plenary and Invited Lecturers at the 25th International Symposium

on Plasma Chemistry (ISPC25), 21-26 May 2023, Kyoto, Japan

- November 13, 2023: Prof. Watanabe has recieved Plasma Innovation Prize, Association of Asia-Pacific Physical Societies, Division of Plasma Physics.

See Review of Modern Plasma Physics.

- September, 2023: Our paper "Effect of Mathane Injection Methods on the Preparation of Silicon Nanoparticles

with Cabon Coating in Induction Thermal Plasma"was selected as Best Paper Award of Journal of Chemical Engieering of Japan.

- May 21-26, 2023: 25th International Symposium on Plasma Chemsitry (ISPC25, Kyoto, Japan), Chair: Prof. Watanabe, Download here

- May 20-21, 2023: IPCS Summer School (Kyoto, Japan), Chair: Prof. Watanabe and Tanaka.

- December, 2021: Prof. Tanaka was promoted to Associate Professor.

- September, 2020: Prof. Tanaka was selected as Trainees of SENTAN-Q (Diversity and Super Global Training Program).

- September 9, 2019: "Kunming University of Science and Technoglogy - Kyushu University Joint Research Center on Plasma Metallurgy Materials" was opened in Kunming, China.

- July 2, 2019: Our paper on The Astrophysical Journal Letters was picked by Physics Today, Making Cosmic Dust in The Lab

- June 11, 2019: Our research about plasma waste treatment was televised on TV program.

- October 12, 2018: Our research about plasma waste treatment was televised on TV program.

- January 1, 2018: The Board of Directors of the International Plasma Chemistry Society.

- September 17, 2017: Our research about plasma waste treatment was televised on TV program.

- April 22, 2016: Our research about plasma waste treatment was televised on TV program.

- November 9, 2014: Our research about plasma waste treatment was televised on TV program. See YouTube

- October 2014: Prof. Watanabe was awarded Plasma Materials Science Awards, Japan Society for Promotion of Sciences, 153rd Committee on Plasma Materials Science.

- March 5, 2012: Our research about plasma waste treatment was televised on Discovery Channel "Rebuilding Japan".

- May 30, 2009: The Prime Minister Observes Advanced Environment-Friendly and Energy-Saving Technology Facilities.

Waste Treatment by Atmospheric Pressure Plasmas can be downloaded from

here.

|

| 1 The subject and aims of research |

|

Thermal plasmas have simply been used as a high temperature source. This indicates that thermal plasmas may have more capabilities in material processing, especially production of high-quality and high-performance materials, if

thermal plasmas are utilized effectively as chemically reactive gases.

Therefore we developed the numerical analysis to investigate non-equilibrium

characteristics in thermal plasmas. These results can be utilized for the

nano-material synthesis as well as waste treatment using thermal plasmas.

|

|

2 Related recent research topics

|

|

Modeling of Reactive Plasma Flows

The induction thermal plasma approach has been applied for many fields, including treatment of harmful waste materials, recovery of useful material from waste, and production of high-quality and high-performance materials, such as synthesis of nanoparticles, deposition of thin films, and plasma spraying. Induction thermal plasmas offer unique advantages including high enthalpy to enhance reaction kinetics, high chemical reactivity, oxidation and reduction atmospheres in accordance with required chemical reactions, and rapid quenching. These advantages increase the advances and demands in plasma chemistry and plasma processing.

However, thermal plasmas have been simply used as high-temperature source,

because argon is typically used as the plasma gas. In some applications

such as reactive plasma spraying, material synthesis, and waste treatment,

thermal plasmas with adding reactive gas are desirable to enhance the chemical

reactivity of the plasma.

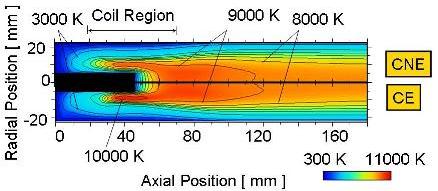

Thermal plasmas have been mainly treated as equilibrium conditions even

though sophisticated modeling considering chemical reactions has been required

for industrial applications. In previous works, estimation of thermodynamic

and transport properties was oversimplified, therefore, more sophisticated

models are required. The oversimplified estimation, such as use of equilibrium

properties and use of the first-order approximation of Chapman-Enskog method,

would cause errors in the numerical results.

In order to improve the accuracy of thermodynamic and transport properties,

higher-order approximation of Chapman-Enskog method was applied for estimation

of the transport properties of induction thermal plasmas. The thermal conductivity

and the electrical conductivity by higher-order approximation differ from

those of the first-order approximation especially over 10000 K.

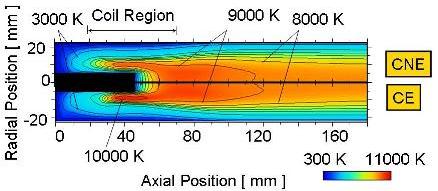

In this study, a non-equilibrium modeling of induction thermal plasmas

was developed without chemical equilibrium assumptions. This formulation

including the finite-rates of dissociation and ionization is presented

using higher-order approximation of Chapman-Enskog method for estimation

of the transport properties.

|

RF plasma temperature distribution for nanoparticle synthesis. |

Comparison of temperature distributions obtained from the chemical equilibrium

model (CE) and from the chemical non-equilibrium model (CNE) for argon-oxygen

induction plasmas.

|

|

|

|

|

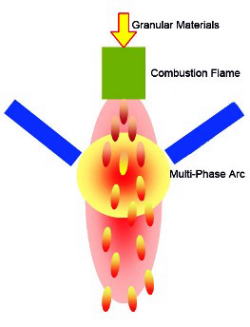

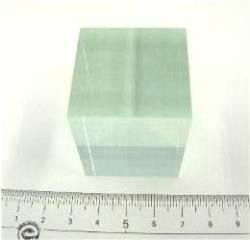

Development of Innovative In-Flight Glass Melting Technology for Energy Conservation

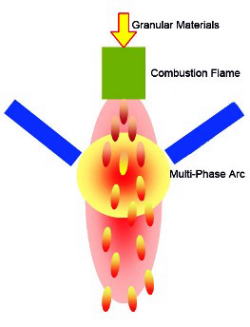

We developed innovative in-flight glass melting technology under the support of New Energy and Industrial Technology Development Organization (NEDO) project in Japan from 2005 until 2012. The granulated raw material with small diameter is dispersed in thermal plasmas and the powders contact fully with the plasma and burner flame. The high heat-transfer and temperatures of the plasma will melt the raw material quickly. In addition, the decomposed gas of carbonates is removed during the in-flight treatment to reduce the fining time considerably. Compared with the traditional glass production, the total vitrification time is evaluated only 2-3 h in the same productivity as the fuel-fired melter. A multiphase AC arc was developed for the application of glass melting technology. The large volume discharge produced by a stable multiphase AC arc is preferable to melt the granulated glass materials. The discharge behavior and the high-temperature region of the plasma can be controlled by the electrode configurations.

The most important invention is the development of multiphase AC arc. The large volume discharge produced by a stable multiphase AC arc is preferable to melt the granulated glass materials. The discharge behavior and the high temperature region of the plasma can be controlled by the electrode configurations. The spatial characteristics of the arc discharge were examined by image analysis of high-speed camera. Results show arc existence area is related with electrode configuration. This study provides the useful information of efficient particle treatment in the preferred electrode configuration.

|

Multiphase AC arc for material processing. |

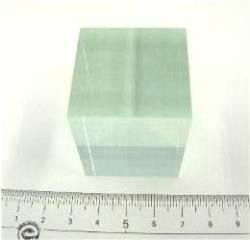

Development of new glass melting technology that can rapidly melt atomized and homogenized granular glass materials.

High-quality glass (porosity < 0.01%) were produced from in-flight melted powders.

|

|

|

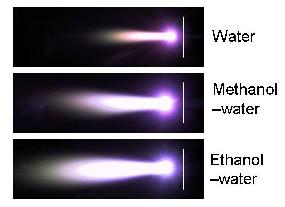

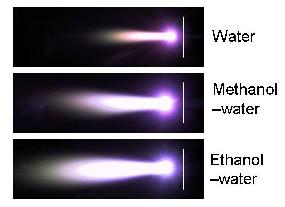

Generation of Water Plasmas under Atmospheric Pressure

DC 100%-steam plasma characteristics were investigated for the application

of halogenated hydrocarbon decomposition. The developed steam plasma system

is a portable light-weight plasma generation system that does not require

any gas supply. The system has high energy-efficiency since cooling water

is not needed. In addition, a dry process was developed for halogenated

hydrocarbon decomposition and simultaneously adsorbing fluorine and bromine

with solid alkaline reactants.

Water plasma system has been scaled up into a mobile system in a vehicle

with direct-current generator. This innovative in-vehicle plasma has great

advantage to reduce the risk and cost caused by the transportation of harmful

wastes. The developed system has been installed at Helix Co. Ltd., Japan

for the waste oil treatment.

Applications for the destruction of hazardous and waste materials such

as halogenated hydrocarbons by water thermal plasmas were developed. For

halogenated hydrocarbon decomposition, key technologies are the stable

generation of DC water plasmas and the off-gas treatment after the decomposition

of halogenated hydrocarbon. Therefore, DC 100%-steam plasma characteristics

were investigated for the application of halogenated hydrocarbon decomposition.

The developed water plasma system is a portable light-weight plasma generation

system that does not require any gas supply. The system has high energy-efficiency

since cooling water is not needed. In addition, a dry process was developed

for the off-gas treatment of halogenated hydrocarbon decomposition using

solid alkaline reactants.

|

Photographs for water plasma, methanol-water plasma, and ethanol-water

plasma for waste treatments.

In-vehicle water plasma jet. |

Water plasma torch for waste destruction. |

|

|

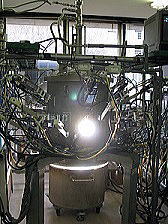

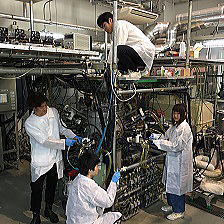

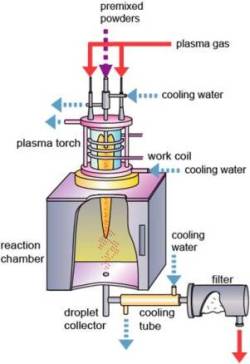

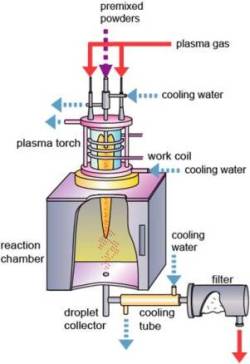

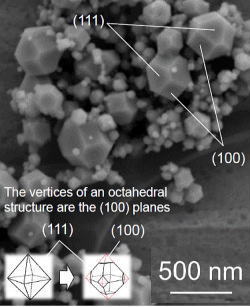

Preparation of Functional Nanoparticles by Thermal Plasmas

Functional nanoparticles of silicide and boride were prepared by induction

thermal plasmas. Silicide and rare-earth boride are attractive materials

because of their high melting temperature, high electrical conductivity

and low work function. Therefore these nanoparticles would be applied for

electromagnetic shielding, and solar control windows with interaction with

IR and UV light.

For the preparation of silicide, Si powder premixed with metal powder (Mo,

Ti, Co, Fe, Cr, or Mn) was injected into the plasma. For the preparation

of rare-earth boride, premixed powders of rare-earth oxide, B and C were

introduced into the thermal plasma. In the thermal plasma, the injected

powders were evaporated and reacted with boron. After the evaporation and

reaction, the vapor was rapidly cooled after the plasma flame. The nanoparticles

were prepared on condition that the vapor was quickly quenched by the water-cooled

copper coil.

We developed transparent radiation shield by making the shield materials into nanoparticles, and we conducted the collaborative project with Japan Atomic Energy Agency (JAEA).

Recently, We developed nanoparticle synthesis for cathode, anode, and electrolyte of lithium-ion secondary battery. These nanoparticles leads to the development of all solid-state lithium-ion battery improvement with high energy density.

We actively extended the research to the investigation of interplanetary

dust particles contain glass with embedded metals and sulfides (GEMS) grains,

which are considered to be among the building blocks of the solar system.

GEMS grains formed either in the local environment of our protoplanetary

disk considering the nucleation and growth of solids from high-temperature

gas during cooling.

Another purpose is to investigate the condensation mechanism of mixture

vapor of feed powders in thermal plasmas. The characteristics of the prepared

nanoparticles are affected by the vapor pressure ratio of the constituent

materials. Investigation of physical and chemical processes in thermal

plasma processing is indispensable for Nanoparticle synthesis.

|

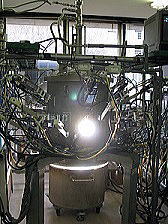

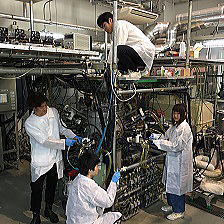

Induction thermal plasma system for nanoparticle synthesis.

Induction thermal plasma system for nanoparticle synthesis. |

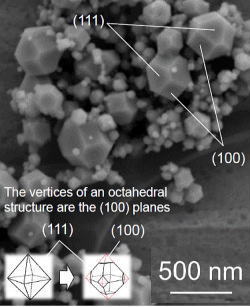

Tetradecahedral Spinel LiMn2O4 were synthesized by RF plasmas for Lithium-ion battery.

Tetradecahedral Spinel LiMn2O4 were synthesized by RF plasmas for Lithium-ion battery. |

|

|

Waste Treatment by Reactive Thermal Plasmas

Attractive thermal plasma processes have been proposed especially for waste

treatment, because engineering advantages such as smaller reactor, lower

capital cost, portability allowing on-site destruction, rapid start-up

and shutdown offer efficient destruction of hazardous and waste materials.

Waste material can be efficiently degraded by thermal plasmas under reducing

or oxidizing conditions. However, thermal plasmas have been mainly used

as a high temperature source. This indicates that thermal plasmas may have

more capability for waste treatment, if thermal plasmas are utilized effectively

as chemically reactive gas.

In this research, application for destruction of hazardous and waste materials

by thermal plasmas is developed. Radioactive waste treatment by thermal

plasmas is an active research field, therefore plasma treatments of low-level

radioactive wastes (LLW) as well as ion-exchange resin are investigated.

Moreover, reactive thermal plasma for halogenated hydrocarbon decomposition

is developed. For halogenated hydrocarbon decomposition, the stable generation

of DC steam plasmas is the important factor for industrial application.

Steam plasmas are suitable for halogenated hydrocarbon decomposition because

hydrogen and oxygen combine with the liberated halogen and carbon atoms

to prevent recombination reactions that result in the reformation of halogenated

hydrocarbons.

|

Thermal plasma jet for waste destruction.

Cobalt doped resins after the plasma treatments. |

Hydrogen generation from waste using thermal plasmas.

Water plasma system for CFC destruction.

|

|

|

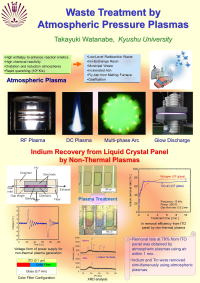

Development of Material Processing by Non-Equilibrium Atmospheric Plasmas

Atmospheric pressure plasma has been studied for the application of material

surface cleaning, preparation of surface coating, and modification of polymer

film. In this study, the atmospheric non-thermal plasmas ere applied to

surface cleaning of waste plastic.

The paint attached to waste plastic surface causes low quality of recycled

plastic. The paint removable is difficult by the conventional dry cleaning

process, therefore new cleaning technology for waste-plastic recycle has

been required.

The mechanism of the cleaning with atmospheric plasmas was investigated

from the measurements of optical emission spectroscopy, the atomic concentrations

of plastics surface were measured with electron spectroscopy for chemical

analysis.

Furthermore, a kinetic model is developed to investigate ozone and oxygen

radical production in dry air treated by a non-thermal plasma jet at atmospheric

pressure.

|

Indium recovery from liquid crystal panel using atmospheric glow discharge.

Indium recovery from liquid crystal panel using atmospheric glow discharge. |

Glow discharge of air under atmospheric pressure.

Glow discharge of air under atmospheric pressure.

Seed treatment by atmospheric glow discharge.

Seed treatment by atmospheric glow discharge. |

|

|

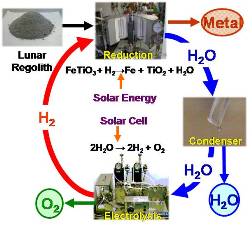

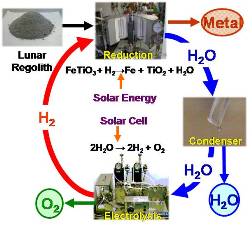

Lunar Resources Utilization

Ground-engineering work on experimental missions for lunar resource utilization

has been conducted. The goal of the research program is to conceptually

design an experiment system for unmanned water production on the Moon,

and to define essential technological breakthroughs.

As part of the research program, an experimental study on hydrogen reduction

of lunar soil has been performed to design a chemical reactor of the water

production. A fixed-bed reduction reactor and lunar soil simulants were

prepared for our water-production experiments.

Over 20 processes of oxygen production on the moon have been proposed.

Among these processes, oxygen production employing hydrogen reduction is

the most feasible process. In this process, ilmenite contained in lunar

soil is reduced with hydrogen producing water. Oxygen is subsequently produced

by electrolysis. Hydrogen produced in reaction can be recycled.

Understanding the hydrogen reduction mechanism of ilmenite is important

for the mission of utilizing lunar soil. The purpose of this work is to

discuss the possibility and the mechanism of water production.

|

Oxygen production form lunar regolith.

Oxygen production form lunar regolith.

Experiment of water production from lunar soil simulant.

|

Water production system by hydrogen reduction of lunar soil simulant. |

|

List of Publications (Plasma Characteristics, Plasma Generations)

List of Publications (Plasma Materials Processing)

List of Publications (Plasma Waste Treatments, Others)

Books, Patents, Projects, Awards |